Fasahar evaporation da crystallization

Molasses barasa ya ɓata ruwa mai tasiri na na'urar fitarwa

Dubawa

Tushen, halaye da cutarwar molasses barasa ruwan sha

Ruwan sharar barasa na Molasses yana da girma mai girma da kuma ruwan sharar yanayi mai launi mai launi da aka fitar daga taron barasa na masana'antar sukari don samar da barasa bayan haifuwar molasses. Yana da arziki a cikin furotin da sauran kwayoyin halitta, kuma ya ƙunshi ƙarin gishirin inorganic kamar Ca da Mg da yawa masu yawa. SO2 da sauransu. Yawanci, pH na ruwan barasa shine 4.0-4.8, COD shine 100,000-130,000 mg/1, BOD shine 57-67,000 mgSs, 10.8-82.4 mg/1. Bugu da kari, galibin irin wannan ruwan dattin acidic ne, kuma launin yana da tsayi sosai, launin ruwan kasa-baki, galibi ya hada da kalar caramel, kalar phenolic, kalar Maillard da sauransu. Tun da ruwan sharar gida ya ƙunshi kusan 10% daskararru, ƙaddamarwa yana da ƙasa kuma ba za a iya amfani da shi ba. Idan aka watsar da shi kai tsaye zuwa cikin koguna da filayen noma ba tare da magani ba, zai haifar da gurbatar ruwa da muhalli sosai, ko kuma ya haifar da rarrabuwar acid da takurewar kasa, da ci gaban cututtukan amfanin gona. Yadda ake magance da amfani da ruwan sharar barasa na molasses babbar matsalar muhalli ce da ke fuskantar masana'antar sukari.

Ruwan sharar barasa na Molasses yana da lalacewa sosai kuma yana da babban chroma, wanda ke da wahalar cirewa ta hanyar hanyar sinadarai. Matsakaicin ƙonawa ko takin ruwa mai inganci shine mafi cikakken tsarin kulawa a halin yanzu.

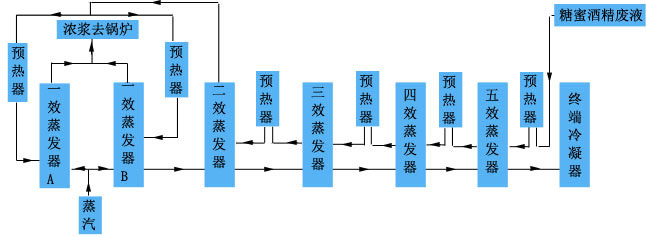

Na'urar tana ɗaukar tsarin watsawa mai ƙarfi mai ƙarfi biyar, tare da cikakken tururi azaman tushen zafi, dumama tasiri guda ɗaya da aiki mai tasiri biyar. Ruwan ruwan barasa na molasses tare da maida hankali na 5 zuwa 6% yana mai da hankali kuma yana ƙafe, kuma ana aika slurry mai ƙarfi mai ma'aunin ≥ 60% zuwa tukunyar jirgi don ƙonawa, kuma zafin da aka samar yana gamsar da tururi don na'urar. Cire ruwan da aka haɗe da shi zuwa sashin da ya gabata don ruwan dilution.

Na biyu, ginshiƙi mai gudana

Na uku, halayen tsari

1. Saita spare evaporator don share kayan, wanda zai iya gane tsaftacewa mara tsayawa kuma tabbatar da ci gaba da samarwa.

2. Na'urar tana ɗaukar sarrafa shirye-shiryen atomatik don adana farashin aiki.

3. High aiki yadda ya dace da kuma barga aiki.

4. Ta amfani da slurry mai kauri don komawa cikin tukunyar jirgi, molasses na iya samar da barasa ba tare da ƙara mai ba.

5. An saita wani spare evaporator don sakamako na fitarwa, wanda zai iya gane tsaftacewa ba tare da tsayawa ba kuma tabbatar da ci gaba da samarwa.

6. Ana iya samar da barasa daga molasses ba tare da ƙara mai ta hanyar kauri mai kauri zuwa tukunyar jirgi don sake amfani da molasses ba.