Aginomoto ci gaba da crystallization tsari

Dubawa

Yana ba da na'ura da hanya don kafawa a kan madaidaicin Layer na semiconductor crystalline.

An samar da Layer semiconductor ta hanyar tururi. Executive pulsed Laser narkewa / recrystallization tafiyar matakai zuwa semiconductor Layer zuwa crystalline yadudduka. The Laser ko wasu pulsed electromagnetic radiation fashe da aka kafa a matsayin uniformly rarraba a kan jiyya yankin, da kuma ci gaba da fallasa zuwa aiki yankin kusa da ya ce fashe, zuwa progressively ajiya abu da aka tuba zuwa crystalline material.Ci gaba da ciyarwa da fitarwa, da kuma maida hankali, zazzabi, crystal slurry yawa da crystal size rarraba duk taya ya kasance ba canzawa a lokacin da crystallization tsari.

1. Don daidaitawa zuwa ci gaba da ka'idojin samar da kayayyaki, ci gaba da sarrafa tsarin samar da daidaito ya fi girma, fitarwa yana da girma, samarwa yana da kwanciyar hankali, kuma yana da dacewa don haɗawa tare da wasu matakai na tsari, wanda shine daya daga cikin hanyoyin ci gaban fasahar masana'antu a nan gaba.

2. The crystallization yawan amfanin ƙasa za a iya ƙwarai inganta, da kuma kayayyakin rasa a cikin uwa barasa za a iya dawo dasu ta hanyar Multi-mataki countercurrent hanya, yayin saduwa da doka bukatun, da kuma ƙwarai rage samar da m m sharar gida kayan.

3. Za'a iya inganta tsabtar samfurin yadda ya kamata, kuma za'a iya ƙara girman matakin rabuwa na babban samfurin da ƙazanta ta hanyar daɗaɗɗen matakai masu yawa, don haka za'a iya ƙara yawan abun ciki na babban samfurin, da ingancin ingancin samfurin. samfurin ƙarshe na iya inganta.

4.Rana karkata tsakanin batches. Ana iya amfani da cikakken sarrafawa ta atomatik da saka idanu akan layi don rage karkatar da aikin hannu ya haifar da rashin kwanciyar hankali da aka samu ta hanyar riga-kafi.

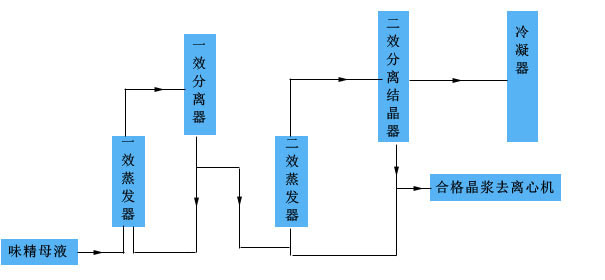

A ginshiƙi na MSG guda-sakamako crystallization tukunya, da na'urar daukar da aiwatar da sau biyu-tasiri, tashin fim, decompression evaporation, sabo tururi samar da zafi zuwa farko-tasiri, idan aka kwatanta da asali tsari, wannan na'urar rage 50% tururi amfani. Crystallization ita ce haɓakar kai ta Oslo elutriation crystallizer ba tare da motsawa ba

Na'urar tana ɗaukar shirin atomatik don sarrafawa.

Na uku, ginshiƙi mai gudana